The Housing Revolution: Everything You Need to Know About Prefab Homes

Prefabricated homes are transforming the housing market with their innovative construction methods and design flexibility. These factory-built structures offer a compelling alternative to traditional construction, combining efficiency, sustainability, and affordability. As housing demands evolve and technology advances, prefab homes are positioned to play an increasingly significant role in addressing global housing challenges.

Prefabricated homes represent a significant shift in residential construction, offering an alternative approach to traditional building methods. These structures are manufactured in controlled factory environments before being transported and assembled on-site. The prefab housing concept has evolved considerably over decades, moving from basic designs to sophisticated, customizable living spaces that can rival or exceed conventional homes in quality and appeal. With advancements in manufacturing technology, materials science, and architectural design, prefabricated homes are increasingly becoming a mainstream housing option for diverse demographics.

What Are Prefabricated Homes and How Do They Work?

Prefabricated homes—often called prefab homes—are dwellings manufactured off-site in sections or modules, then transported to their final location for assembly. Unlike traditional construction, where building occurs entirely on-site and is subject to weather delays and other variables, prefab construction takes place in controlled factory settings. This approach offers several advantages, including precision manufacturing, reduced waste, and faster completion times.

The prefab process typically begins with architectural design, followed by factory production of components or modules. These elements are then transported to the building site, where they’re assembled on a pre-prepared foundation. Depending on the prefab type, this assembly might involve connecting several large modules or assembling numerous smaller components. Modern prefab homes range from modest, affordable options to luxury custom designs with high-end finishes and innovative features.

Prefabricated Homes Costs: Understanding the Investment

The cost of prefabricated homes varies significantly based on several factors, including size, design complexity, materials, finishes, and geographic location. Generally, prefab homes can cost between $100 and $200 per square foot, though basic models may start lower while custom luxury versions can exceed this range. This pricing typically includes the home’s manufacturing but may exclude site preparation, foundation work, transportation, assembly, and utility connections.

One of the primary financial advantages of prefabricated homes is cost predictability. The factory-controlled environment minimizes unexpected expenses common in traditional construction. Additionally, the shorter construction timeline reduces financing costs during the building phase. However, potential buyers should be aware that while the initial home price might seem lower than stick-built alternatives, the total project cost—including land, site work, and finishing—can sometimes approach that of conventional construction, particularly for high-end prefab designs.

Prefabricated Homes Comparison: Types and Styles

Prefabricated housing encompasses several distinct categories, each offering different benefits and considerations:

Modular homes consist of multiple box-like modules manufactured in factories, transported to the building site, and assembled on permanent foundations. These homes must meet the same local building codes as traditional houses and are generally indistinguishable from site-built homes once completed. They offer extensive customization options and can be multi-story structures.

Manufactured homes (formerly known as mobile homes) are built entirely in factories on non-removable steel chassis and transported to the site. They must comply with federal HUD code rather than local building codes and typically offer less design flexibility than modular homes.

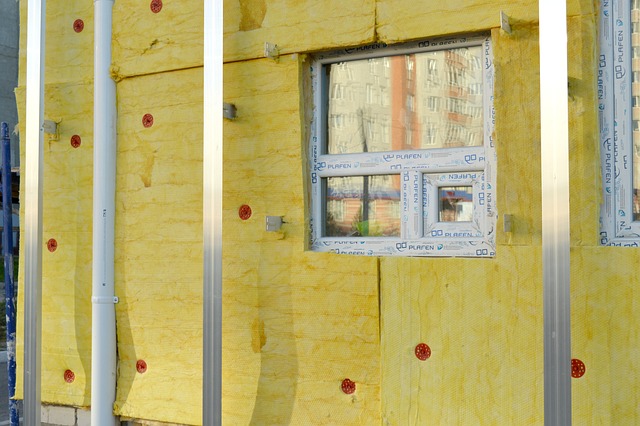

Panelized homes involve factory-built panels—complete wall systems with windows, doors, wiring, and exterior siding—that are transported to the site and assembled. This approach combines some prefab efficiency with greater design flexibility.

Kit homes provide pre-cut, pre-engineered materials shipped to the building site for assembly, offering a middle ground between prefab efficiency and custom building.

Future Trends: Prefabricated Homes 2025 and Beyond

The prefabricated housing industry is experiencing rapid innovation that will likely accelerate through 2025 and beyond. Technological advancements in manufacturing processes, including automation and robotics, are improving precision while reducing costs. Building information modeling (BIM) and 3D printing technologies are enabling more complex designs and greater customization options.

Sustainability is becoming a central focus, with many manufacturers incorporating energy-efficient systems, sustainable materials, and zero-waste production processes. Smart home technology integration is increasingly standard, with prefab homes designed to accommodate advanced home automation systems from the factory.

Market analysts project continued growth in the prefabricated housing sector, driven by housing shortages in urban areas, rising construction costs, and increasing consumer awareness of prefab benefits. As climate concerns intensify, the reduced environmental impact of factory production compared to on-site construction may further accelerate adoption.

Prefabricated Homes Prices: Market Comparison

When evaluating prefabricated housing options, understanding the market landscape helps potential buyers make informed decisions. The following table compares several established prefabricated home providers across different price points and offerings:

| Provider | Home Type | Size Range (sq ft) | Base Price Range | Notable Features |

|---|---|---|---|---|

| Clayton Homes | Manufactured | 1,000-2,500 | $80,000-$200,000 | Energy-efficient options, nationwide availability |

| Blu Homes | Premium Modular | 600-3,600 | $195,000-$545,000 | Fold-out technology, high-end finishes |

| Method Homes | Custom Modular | 800-2,800 | $175,000-$600,000 | LEED-certified options, contemporary designs |

| Connect Homes | Modern Modular | 640-3,200 | $180,000-$500,000 | Shipping container-based architecture |

| Plant Prefab | Custom Panels | 400-3,500+ | $170,000-$500,000+ | Sustainable materials, patented building system |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Considerations Before Choosing a Prefabricated Home

Before committing to a prefabricated home, prospective buyers should consider several important factors. First, understand local zoning regulations and building codes, as some areas have restrictions on certain types of prefabricated structures. Financing can also be more complex for prefab homes; while modular homes typically qualify for conventional mortgages, other prefab types might require different financing approaches.

Land selection and preparation represent significant considerations and costs. The site must be accessible for delivery of modules or components, which may require special permits for transportation. Foundation requirements vary by prefab type and local conditions, potentially adding substantial costs to the overall project.

The level of customization available differs widely between manufacturers and prefab types. Some offer extensive design flexibility, while others provide limited options. Similarly, the timeline advantage of prefab construction can vary—while the factory building process is faster than traditional construction, factors like manufacturer backlog, shipping logistics, and site preparation can affect the overall project schedule.

Prefabricated homes represent a compelling housing alternative combining efficiency, sustainability, and modern design. As technology advances and housing needs evolve, these factory-built structures continue gaining market share and consumer acceptance. Whether driven by cost considerations, environmental concerns, or design preferences, the growing interest in prefabricated homes reflects their ability to address contemporary housing challenges while offering quality living spaces tailored to diverse needs and budgets.