The Potency of Miniaturization in Industrial Operations: A Detailed Perspective

Industrial miniaturization, the process of reducing the size of products, components, or processes while maintaining or enhancing their functionality, has been a pivotal aspect of industrial development since the emergence of the semiconductor industry. One of the remarkable examples of this evolution is the transformation of computers, which once occupied entire rooms, into handheld devices with more computing power.

Miniaturization has been driven by advancements in materials science, precision engineering, and microfabrication technologies. It has found wide applications in various sectors including electronics, pharmaceuticals, automotive, and aerospace, allowing for improved functionality, cost reduction, and resource optimization.

Current Trends and Practical Applications

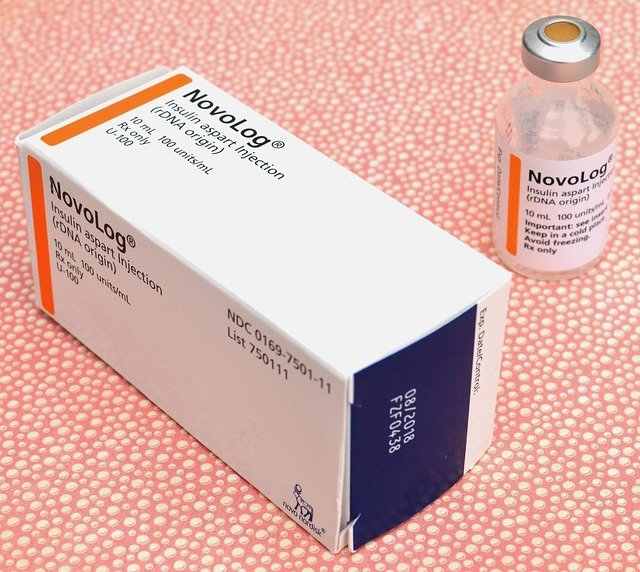

Today, miniaturization is a critical factor shaping innovations across industries. For instance, in the pharmaceutical industry, miniaturized drug delivery systems are being developed to improve drug efficacy and patient compliance. In the automotive industry, miniaturized sensors are used for advanced driver assistance systems (ADAS) to enhance vehicle safety.

The significance of miniaturization extends to environmental sustainability as well. Miniaturized devices use less material and energy, thereby contributing to reduced environmental impact.

Impact, Benefits, and Challenges of Miniaturization

Miniaturization has a profound impact on industrial operations. It allows industries to produce more compact, efficient, and powerful products. It also enables the development of portable and wearable devices, thus enhancing user convenience.

However, miniaturization also presents certain challenges. As devices become smaller, controlling heat dissipation becomes increasingly difficult. Also, the manufacturing of miniaturized components requires high precision, which can increase production costs.

Insights from Research

Research indicates that further advancements in miniaturization will likely be driven by nanotechnology, allowing for the development of devices at the atomic and molecular scale. This could revolutionize various industries, leading to the creation of more efficient and sustainable products and processes.

Practical Insights on Miniaturization in Industrial Operations

-

Embrace miniaturization as a strategic approach to product design, considering its potential to enhance functionality and user experience.

-

Invest in research and development to overcome the challenges associated with miniaturization, such as heat dissipation and precision manufacturing.

-

Consider the implications of miniaturization on sustainability, given its potential to reduce material and energy consumption.

In conclusion, miniaturization is a powerful tool for innovation in industrial operations. While it presents certain challenges, its potential benefits in terms of improved functionality, user convenience, and environmental sustainability make it a worthy area of focus for industries. As advancements in technology continue, the future of miniaturization appears promising, with potential to revolutionize various aspects of industrial operations.